West Virginia’s White-Washed Heritage

The power of the media to shape public opinion has always been with us since the foundation of our state, as well as our country. You could liken our nation’s founding to a union organizing drive, with all the elements of an indifferent and unresponsive ruler, his cruel and brutal lackeys, brave agitators and organizers who speak out in speech and print against injustice, and those under the thumb of the ruler who dare rise and and demand a better lot in life.

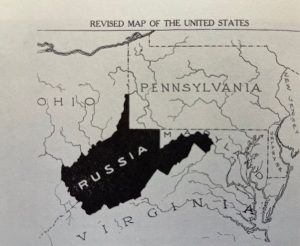

West Virginia was born out of internal strife within our union of the United States due to inequalities between the wealth of the industrializing northern states and the predominantly agrarian, slave holding, southern states. The West Virginia economy was more tied to that of it’s northern neighbors of Ohio and Pennsylvania, so the newly hatched state sided with the Union, with it’s first capital established in our northern panhandle of Wheeling. The reality was that the divide in our country was a bleeding gash right across the middle of our state, with the first land battle famously being fought in Philippi.

No doubt had the Confederacy won, Virginia would have reasserted it’s control over it’s western rogue territory, or, had those forming our state had sided with the southerners, the battle lines for the Civil War would’ve been redrawn and the survival of West Virginia as a separate state would have been highly doubtful.

Since 1865, our state has yet to establish itself as an integral part of the fabric of America and distinguish itself with a unique culture and identity of our own. This despite the many famous people born in or with strong ties to our state. Educators Booker T. Washington and Henry Lois Gates; novelists like John Knowles, Stephen Coonts, or Jebediah Purdy; famed aviator Chuck Yeager, WWII Medal of Honor recipient Hershel “Woody” Williams, and Basil L. Plumley who featured prominently in the Vietnam War movie “We Were Soldiers“. We’ve had our share of other famed entertainers and sports figures. Coaches Lou Holtz, Jimbo Fisher, and Nick Saban all hail from West Virginia, as well as entertainers Steve Harvey, Ted Cassidy (Lurch from The Adams Family), Morgan Spurlock, John Corbett, Virginia Egnor (Dagmar), Conchata Ferrell, Kathy Mattea, Peter Marshall, as well as many others.

Since 1865, our state has yet to establish itself as an integral part of the fabric of America and distinguish itself with a unique culture and identity of our own. This despite the many famous people born in or with strong ties to our state. Educators Booker T. Washington and Henry Lois Gates; novelists like John Knowles, Stephen Coonts, or Jebediah Purdy; famed aviator Chuck Yeager, WWII Medal of Honor recipient Hershel “Woody” Williams, and Basil L. Plumley who featured prominently in the Vietnam War movie “We Were Soldiers“. We’ve had our share of other famed entertainers and sports figures. Coaches Lou Holtz, Jimbo Fisher, and Nick Saban all hail from West Virginia, as well as entertainers Steve Harvey, Ted Cassidy (Lurch from The Adams Family), Morgan Spurlock, John Corbett, Virginia Egnor (Dagmar), Conchata Ferrell, Kathy Mattea, Peter Marshall, as well as many others.

Sadly, if you ask someone unfamiliar with our state, they will inevitably identify us as progenitors of the Hatfields and McCoys. Those famed feuders have long, and wrongly, been stereotyped as backwards, uneducated, crude, hard-headed, moonshine drinking hillbillies. Anybody actually familiar with the circumstances of the troubles between the two families know it was a tale that included politics, business, and power between two determined and shrewd patriarchs of rugged pioneering dynasties in direct opposition to each other.

That’s where the story of West Virginia ends, as far as what the rest of the country is concerned. The media has portrayed us by those long set preconceptions, as we labored quietly powering the country by harvesting and selling off our abundant natural resources, with the hard work of our fellow Mountaineers.

That’s where the story of West Virginia ends, as far as what the rest of the country is concerned. The media has portrayed us by those long set preconceptions, as we labored quietly powering the country by harvesting and selling off our abundant natural resources, with the hard work of our fellow Mountaineers.

But why quietly?

It has been said that history is written by the victors, which explains why no other perspective has ever been offered to counter the notion of violent and stand-offish inbreds who sit around on their front porch spitting tobacco and taking potshots at neighbors as well as strangers who dare enter their domain.

Truth is, the Hatfields and McCoys are a relatively harmless and safe piece of our heritage that the media has edited, massaged, and expounded on for easy consumption by the American public. It’s a multi-layered story that can be safely tapped into to siphon off profit in literature, movies, and by marketing the lore surrounding those colorful characters involved in the long running dispute.

Truth is, the Hatfields and McCoys are a relatively harmless and safe piece of our heritage that the media has edited, massaged, and expounded on for easy consumption by the American public. It’s a multi-layered story that can be safely tapped into to siphon off profit in literature, movies, and by marketing the lore surrounding those colorful characters involved in the long running dispute.

True West Virginia heritage and culture is firmly rooted in America’s labor history and unions. It’s a taboo subject that those of power and influence have sought to erase, hide, or gloss over in our society.That’s why you get Hatfields and McCoys, not Frank Keeney and Fred Mooney, you get Thomas “Stonewall” Jackson and not “General” Bill Blizzard, you get the “Mothman” and not “Mother” Mary Harris Jones. On a larger scale, there have been a multitude of movies depicting the gunfight at the O.K. Corral, but only one notable film that depicts the Matewan Massacre; plenty of gangster movies showing one group of mobsters against another, while The Battle of Blair Mountain remains shrouded in murky history and legend. They give you Jesse James, when what our nation sorely needs is Sid Hatfield, who battled and died in the service of others and not for his own enrichment; sure, everyone knows the names Al Capone and John Dillinger, but not John L. Lewis, Eugene V. Debbs, or Joe Hill.

So why is such an important piece of our West Virginia, as well as American, heritage being suppressed?

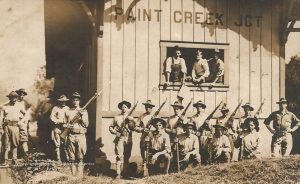

It’s because the “great” industrialists who wrongly get the credit for building our country wish it so. Men like Andrew Carnegie of US Steel, or John D. Rockefeller of Standard Oil, Financier Jay Gould, J.P. Morgan, the Vanderbilt railroad empire, Henry Ford, and many others and their sycophants would have to answer for the crimes they either perpetrated themselves or, as more the case, had their heavily bribed and corrupt politicians, policemen, and thugs. Heavy-handed Baldwin-Felts detectives the coal mines employed as private security, as well as enforcers, and more the same for the Pinkerton Detectives. If these forces were too small, the rich could always rely on a corrupted county or statehouse to dispatch Sheriffs Deputies and their posses, the State Police, and even the National Guard to beat back workers who refused to be shackled into economic and perpetual slavery at the hands of their employers.

It’s because the “great” industrialists who wrongly get the credit for building our country wish it so. Men like Andrew Carnegie of US Steel, or John D. Rockefeller of Standard Oil, Financier Jay Gould, J.P. Morgan, the Vanderbilt railroad empire, Henry Ford, and many others and their sycophants would have to answer for the crimes they either perpetrated themselves or, as more the case, had their heavily bribed and corrupt politicians, policemen, and thugs. Heavy-handed Baldwin-Felts detectives the coal mines employed as private security, as well as enforcers, and more the same for the Pinkerton Detectives. If these forces were too small, the rich could always rely on a corrupted county or statehouse to dispatch Sheriffs Deputies and their posses, the State Police, and even the National Guard to beat back workers who refused to be shackled into economic and perpetual slavery at the hands of their employers.

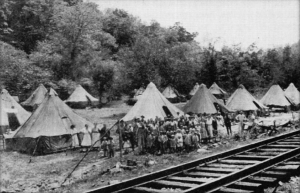

A shameful number of men, women and children were assaulted, maimed, starved, or killed at the hands of employers they served. Here in West Virginia, mothers and fathers were thrown out into the street with all their belongings and left to the mercy of the elements because someone told a gun thug the worker possessed, talked about, or supported the union. These families were forced to the backs of hollers with nothing between them and nature but a thin canvas tent. In those small clusters many died of starvation, disease, exposure, or the frequent bullets that seemed to always be flying around.

A shameful number of men, women and children were assaulted, maimed, starved, or killed at the hands of employers they served. Here in West Virginia, mothers and fathers were thrown out into the street with all their belongings and left to the mercy of the elements because someone told a gun thug the worker possessed, talked about, or supported the union. These families were forced to the backs of hollers with nothing between them and nature but a thin canvas tent. In those small clusters many died of starvation, disease, exposure, or the frequent bullets that seemed to always be flying around.

Whether it was the Pullman Strike, the Triangle Shirtwaist fire. the Haymarket Riots, the Paint Creek and Cabin Creek strike, the Ludlow Massacre, or many other major eruptions of frustrated and desperate workers, the masters of business and industry would have a lot to answer for. The indiscriminate beatings, destruction of property, denial  of constitutionally granted rights, subversion, spying, and almost any other indignity that can or can’t even be imagined.

of constitutionally granted rights, subversion, spying, and almost any other indignity that can or can’t even be imagined.

The war goes on today. Powerful forces have used their media mouthpieces, slick political lapdogs, and vast sums of money to pit neighbor against neighbor, American against American, and justify their treachery both in court and in front of the news cameras. All the while they incrementally push the working class closer and closer to the coal camps they left only a couple of generations ago, while proclaiming themselves servants and pillars of Christianity.

How bad is it?

The tern “redneck” used to refer to the red kerchiefs strikers wore to recognize friends from foes, but now it’s used in a derogatory sense to indicate the ignorant and uncouth. They call trade unionists communists, socialists, and/or fascist to the point that, though describing different political philosophies, the words have mutated into synonyms for each other.

To clear this up, a fascist is one man at the top calling the shots and holding all the wealth themselves. A communist believes no one should be rich, A capitalist believes in oligarchy, made up of many want to be fascist willing to sacrifice anybody as long as it increases their coffers. A socialist has no problem with people being rich, they just believe in a wealthy society no one should be so poor that they cannot live.

Before unions, every employer was a fascist; “my way or the highway.”

Many try to paint unionism as socialist or communism (which is not true since you can’t be either and belong to an American union), but what unions actually do is bring democracy to the shop floor, for every worker equally.

To fight this trend, working people have to actively search and study their missing heritage for themselves and reclaim the rights granted them by the blood and tears shed by men, women, and children for all workers to have a better life for them and their families.

Let this be your New Years resolution!

Merry Christmas and Happy New Year!

Things You Need to Know about “Right to Work”

So far, 28 states have enacted RTW (Right To Work) laws, predominantly in the South and Southwest. While right-to-work laws have nothing to do with rights, work, or guaranteeing jobs for workers, some in the business community view it as a strategy for attracting new businesses to locate in West Virginia, despite its downside risks of lowering wages and hurting unions that helped build the middle class in our country.

Here are five important things you need to know:

1. It’s about lowering wages and eroding workplace protections. As an economic development tool, the professed aim of RTW is to reduce the power of unions by depriving them of resources (dues), which ultimately weakens the union and strengthens the employers’ hand in bargaining for lower pay and benefits. By decreasing the likelihood that businesses will have to negotiate with their workers, this will lower labor costs, reduce the cost of doing business, and will supposedly be an incentive for out-of-state manufacturers and other businesses to locate in West Virginia. If RTW didn’t lower wages and weaken workplace protections across the board, there would be no incentive for companies to move to West Virginia. This, in a nutshell, is the hope of RTW supporters such as the West Virginia Chamber of Commerce.

2. Academic research is unanimous that RTW reduces unionization. While there is no strong evidence that RTW laws help or harm a state’s economy, there is a broad academic consensus that it weakens labor unions. If this happens, it could mean even worse economic and social outcomes in the state. This is because unionization is strongly associated with higher economic mobility, less income inequality, higher wages, safer workers conditions, better benefits and larger voter turnout.

3. The WVU report on RTW is fundamentally flawed. While a recent study by John Deskins at West Virginia University concluded that RTW would boost jobs in West Virginia, the study is fraught with basic design problems. For example, the WVU study misidentifies that Texas and Utah adopted RTW in the 1990s, when both states adopted RTW before 1960. The WVU study also failed to adopt a standard academic practice that accounts for unobserved differences between states, such as the advent of air-conditioning in the South, access to oversees markets, and other important state characteristics. When researchers at the Economic Policy Institute accounted for these problems and replicated WVU’s findings, they found no relationship between RTW status and employment growth. Tim Bartik, an economist with the Upjohn Institute and one of the country’s leading economic development experts, recently reviewed the WVU study and concluded that it “does not provide any convincing evidence that a state that adopts RTW laws will, as a result, experience faster job growth.” The flaws with the WVU study highlight why state policymakers should not rely on its conclusions to adopt RTW.

4. RTW is not about “workplace freedom.” While RTW proponents define ‘workplace freedom” as letting workers opt out of paying a representation fee to pay for the benefits they are receiving under any negotiated union contract, most would define workplace freedom as being treated with dignity and respect on the job. That means getting paid an honest wage for an honest day’s work, and having access to benefits such as paid sick days, paid family leave, health care, and a retirement plan. The only freedom workers would receive if RTW were enacted is the ability to get something for nothing.

5. Low workforce skills are the central reason for West Virginia’s economic woes, not lack of RTW. A recent in-depth study by the Center for Business and Economic Research at the University of Kentucky that explored why the state is so poor found that the shortage of skilled workers – not RTW – was the central reason for the state’s relative poor economic performance. Since West Virginia faces many of the same social and economic problems as Kentucky, policymakers would be well advised to promote polices that improve the skills of the state’s workforce instead of RTW that could reduce workforce training.

The legislature in West Virginia must learn that we can’t build West Virginia by tearing down working families and unions. Instead we need to focus on the policies that we know work, such investing in early childhood education, research and development, higher education, workforce training, and effective ways to help more people get out of poverty.

The Passion of Those Who Support 304

The reason union organizing drives and drives to de-certify a union can get so tense and adversarial is because those who favor unionization are passionate about it and willing to stand up and defend it.

The act of forming a union, especially in this day and age, is an uphill battle. Corporations have shown a willingness to spend millions of dollars to deny workers the right to organize by hiring mercenary labor relations firms who basically come in and take over managing the plant and galvanize every company manager and supervisor against the organizing effort. They will bend the rules, to the point of breaking, and enlist fear and division to strong arm the workers into voting against their own best interests to reject being union.

UWUA Local 304’s story is a great example of workers demanding a say in the workplace that sustains them.

UWUA Local 304’s story is a great example of workers demanding a say in the workplace that sustains them.

Monongahela Power Company was an old, solid, and respected utility back in the days when companies were based locally and they took active and positive interest in the customers they served and cared for the employees that made them successful. These were the days when the Plant Director actually had the authority and power to make decisions at the local level and the integrity to reject initiatives from company stooges that were not in the best interests of the plant or people. Many of the old veterans of Harrison Power Station described the atmosphere created by that kind of leadership as being a part of an extended family of working people with the noble mission of keeping their neighbors safe by making sure the electric stayed flowing.

Then along came Allegheny Energy, which consolidated many small local utilities into one conglomerate. This was the era of Enron and de-regulation that stoked the greed of opportunistic business men and got them interested in utilities. You see, before all that happened, most utilities were thought of, in the financial world, as stodgy widow and orphan stocks that reliably paid meager dividends and were run by dull geeky engineering types with thick glasses and pocket protectors.

The employees of Harrison helplessly watched as the money men took over, the old management was retired and replaced with “yes men” who blindly took orders from the home office, and soon the company was “diversifying” into unfamiliar “ventures” while the discipline and money that kept their primary mission of making and distributing power went away.

While the business executives looked for ways to leech every dollar out of the company, this led to years of high handedness by local management, favoritism, nit-picking, wage disparity, and the workplace being dominated by backstabbers, double dealing, and infantile behavior of managers with huge unchecked egos; the employees said enough is enough and began organizing.

Of course, just saying you’re organizing can get you fired in many shops, and always paints a target of the back of those who carry the fight. The workers at Harrison were no different then as they are now, except maybe a little older. They were all people who had wives, kids, grand-kids, mortgages, car payments, and all the normal pressures many of us still have, but they believed in the need to draw a line in the sand and have a voice in their workplace.

Anyone who has never been through an organizing campaign can never understand the kind of stress these people endured or the amount of risk they faced just for standing up and exercising the often denied right to form a union. Those who went through this came out as brothers in arms, veterans of the war on workers.

That’s where the passion comes from. It came from workers standing together and doing something meaningful to protect the jobs each one relied on. When anyone who participated in that feat hears someone bash the union, threaten to vote it out, or flippantly assert that all they have to do is vote a union back in if they don’t like being non-union , it really ignites a fire in them because they lived through what it takes to get a union in place so that we can deal with our corporate owners on a fair and even plain.

That’s where the passion comes from. It came from workers standing together and doing something meaningful to protect the jobs each one relied on. When anyone who participated in that feat hears someone bash the union, threaten to vote it out, or flippantly assert that all they have to do is vote a union back in if they don’t like being non-union , it really ignites a fire in them because they lived through what it takes to get a union in place so that we can deal with our corporate owners on a fair and even plain.

Kid yourselves if you want to, but doubt runs high that anyone who would work to break a union could ever muster the kind of courage it takes to organize a successful union drive, even if another union would have us after de-certifying, which is highly unlikely. A union is about looking out for each other, while breaking a union is about a few individuals pursuing interests that only benefits them at the cost of everyone else.

Be smart- STAY UNION!

Labor Day Is About U(nion)!

Which of these do you currently have:

___ Homeowners Insurance

___ Automobile Insurance

___ Health Insurance

___ Life Insurance

If you checked ANY of he above, have you considered protecting the ONE thing that allows you to afford coverage for the things you’ve worked so hard for?

Wouldn’t it be nice if you could have job insurance? The kind that protects your job from unfair persecution by those above you with whom you may disagree, protection against being unjustly accused or even fired?

That’s what a UNION is! If something just arise at work that threatens your earning ability, whether that be an overtime issue, a seniority issue, or disciplinary actions against you that affect your wages or job; a UNION is the only mechanism you have to effectively fight any of the above, and more.

Corporations have entire departments for their legal protection, heavily staffed with attorneys, para-legals, researchers, and staff, and ready to jump to the defense of the company at a moments notice. Don’t you, as a worker, deserve the same resources if your livelihood is threatened?

Now, out of the insurance coverage types listed above, which gives you a refund if you don’t use them. Do you get you homeowners premiums back if your house doesn’t burn down? Do you get your car insurance money back if you don’t crash your car? Do you get any type of rebate or refund on your healt or life insurance if you don’t get sick or die? The answer is, “NO!”

Even if you don’t attend your union meetings or take advantage of any of the benefits that being in a union offers, at the very least, you still have the resources and experience of a national organization and local representation who will fight for you.

Here’s the kicker, except for the last few years, union dues have been tax deductible. If the current Administration has it’s way, they will be again.

If you think you can decertify a union and then just vote one back in if you don’t like the changes that happen afterwards, then you have no idea how hard and brutal a union organizing campaign is. The UWUA invested years and money in Harrison Power Station joining them. When a union decertifies, no other union wants to affiliate with a workforce that exhibited such reckless and short sided view of their workplace and their role in it. They won’t.

If you are lucky enough to belong to an established union, Labor Day is all about YOU!

Dissemination of Information

There are some people who may ask what YOUR union uses as a basis for the information we put out to the membership.

In an age when information is used as a weapon to manipulate and control people’s thoughts and actions, it’s a fair question to ask.

The answer is simple, we are part of a network that has over eighty years of experience, the Utility Workers Union of America, and the lessons learned in bargaining three contracts, one of which was turned down twice, and two that we adopted and worked under since we became a union in 2010.

When we tell the membership the things they could lose or that may change, it’s based on past negotiations and actual proposals YOUR union has seen presented to us over the past decade.

What would happen if UWUA Local 304 would go away?

Anybody who tells you that they KNOW what will happen is a liar. Truth is, nobody knows for sure.

When 304 was organized, the general consensus among those immersed in the effort was that we were being bought just for our Transmission and Distribution within the lucrative PJM RTO.

When 304 was organized, the general consensus among those immersed in the effort was that we were being bought just for our Transmission and Distribution within the lucrative PJM RTO.

When this opinion was shared with those less informed, they laughed, pointing out all the large and profitable plants in our system, and how THEY were the real assets.

Here we are in 2021, and no one is laughing anymore. There is nothing funny about closed plants, displaced workers, and less reliable and secure generation being readily available too feed America’s hungry power grid.

In these uncertain times, it’s YOUR union that maintains a certain amount of stability for our members. With our CBA’s Successors and Assigns clause, and language concerning furloughs, layoffs, and bumping rights; it doesn’t matter what company’s sign is out in front of the plant, our members can rest assured that if there’s smoke out the stack, they will have a job.

You can ask, “what has the union done for me?”

At the very least, YOUR union has kept the wolf from the door in a time when coal is being attacked, companies are being bought and sold, and times are less than certain.

Dues Paid vs. Paying Dues

UWUA Local 304 has seen many changes in it’s eleven years of existence, one of the most remarkable is the amount of retirees and new faces we’ve had. Many of the ‘old-timers’ who were around when 304 was organized are now gone, and not enough remain to inform and educate our new Brothers and Sisters about conditions that existed at Harrison before the union and what many members endured when organizing 304.

After Allegheny Energy flirted dangerously with bankruptcy, and the stock price plummeted, the managers credibility at the plant took a hit when it came to preaching the gospel of the company and the evils of a union. Not surprisingly, it was soon announced that we were “merging” (a.k.a. being bought) by First Energy. FE was a total unknown to most of us who knew Duke, AEP, Dominion and other power company’s adjacent to our service area.

After Allegheny Energy flirted dangerously with bankruptcy, and the stock price plummeted, the managers credibility at the plant took a hit when it came to preaching the gospel of the company and the evils of a union. Not surprisingly, it was soon announced that we were “merging” (a.k.a. being bought) by First Energy. FE was a total unknown to most of us who knew Duke, AEP, Dominion and other power company’s adjacent to our service area.

Harrison employees banded together, shared what they learned of our new owner, and decided that organizing with the Utility Workers was the best chance to protect their wages, benefits, and working conditions at our plant. However, our new owner had their own plans.

What followed was a bitter campaign for the organizing committee, assisted and advised by the UWUA, against the expensive and ruthless hired guns of the company who aggressively sought to defeat and confound the efforts in unionization.

There were the standard tactics of captive audience meetings, one of which featured outgoing Allegheny millionaire CEO Paul Evanson, as well as one on one meetings between managers and employees to exert enormous pressure on each individual to vote against the union.

In addition to the standard litany of half-truths, distortions, and outright lies, there were even more nefarious actions taken against union supporters. Some of the more outrageous examples of these were:

- a senior and respected maintenance man was sent home for three days, without pay, for an act of insubordination when accused of throwing a booster fan door. The membership took up a collection for him.

- an operator who was also given three days off for tripping the wrong breaker on an offline unit. Another collection was taken up.

- a coal handler who was fired for a vehicle accident on the coal pile. The union fought and saved his job.

- a manager/supervisor who telephoned an employee’s wife to lie to her that her husband really wasn’t working the overtime he claimed to her that he was.

- there were man other acts of intimidation committed, both known and some not, many consisting of aggressive management making mountains out of mole hills.

If an employee was a known union supporter, they were painted as a target and faced an all out assault by management to make them seem disloyal, dishonest, and incompetent, all at the direction of their high paid union-busters.

If an employee was a known union supporter, they were painted as a target and faced an all out assault by management to make them seem disloyal, dishonest, and incompetent, all at the direction of their high paid union-busters.

Harrison employees knew the only real power a union has is when they all stick together, and they did. They put it all on the line; their careers, benefits, retirement and reputations to endure and support each other during these tumultuous times.

In the end, Harrison employees voted for the Utility Workers Union of America as it’s exclusive bargaining agent with the company, which locked all the things that made working at Harrison a good job into what was called “status-quo”. This basically meant that First Energy could not just come in a make huge changes that affected the newly established bargaining unit without those changes being bargained and agreed to by the union.

This started a second act of intimidation, abuse, and delaying tactics in reaching a contract. It took four years, in which time the company attempted to deny wage increases and variable pay/Short Term Incentive pay due to employees, while chipping away at the state of status-quo that they were legally binding to observe, but ignored.

This started a second act of intimidation, abuse, and delaying tactics in reaching a contract. It took four years, in which time the company attempted to deny wage increases and variable pay/Short Term Incentive pay due to employees, while chipping away at the state of status-quo that they were legally binding to observe, but ignored.

This forced the union, through our first elected Executive Board, to take many complaints of the company’s actions to the National Labor Relations Board (NLRB). In the meantime, while legal battles raged, the company attempted to de-certify the union by petitioning for another union vote. To their great surprise, this vote revealed a growth of support FOR the union compared to the initial vote.

After almost four years, a $1.25 million dollar judgement against the company won by the union and a contract bargained with 304’s second bargaining committee, we began the process of being a union.

After almost four years, a $1.25 million dollar judgement against the company won by the union and a contract bargained with 304’s second bargaining committee, we began the process of being a union.

UWUA Local 304 started with a federally mediated contract as it’s foundation, something that rankled many members who came from other long and well established unions with contracts built and evolved over decades.

Paying dues is the first thing those who knock organized labor seize on when arguing unions. The reason is simple; being union gives you the legitimate legal status to act, but doesn’t pay for representation when you do. That is why we pay dues to pay our own officers when acting in our behalf and legal counsel to support us when we need it.

Never forget about the dues already paid by those who came before that affords you these rights. Take them for granted and they will be gone. Union power is derived by a united membership all pulling together.

Read the article that appeared in The Utility Workers magazine in December, 2001, about Local 304.

Management Schemes Part 3 – Putting Together a Plan

Imagine this. The personnel manager calls a meeting with the union committee one day and makes the following announcement:

“Because of increased external and internal competition, we have to make some changes around here. Starting next week, we will begin to implement direct flow technology with elements of kaizan layered in. We’ll all work together on this so the self- directed teams will begin immediately to exercise their empowerment and direct the reorganization.”

The union committee says “What?”

To which the boss replies, “We don’t know the details of what this means, it’s up to the employees, but to help facilitate the process we have hired the consulting firm of Speedum & Up. They will facilitate the entire process.”

What does the union do when the employer approaches the union with a management scheme like this or like any of the others that the UE Steward has outlined in the last two issues?

- Stop, think, analyze;

- Assert the union’s rights as collective bargaining agent;

- Ask questions, and demand answers;

- Analyze and figure out what the employer really wants;

- Discuss problem with the union members, stewards, national union representatives;

- Educate the union members, stewards if necessary;

- Decide what the union wants, and make a plan;

- Negotiate with the employer and get an agreement in writing.

If the employer bypasses the union and begins to implement a new program, then the union must immediately go to step two and assert the union’s rights as the sole and exclusive collective bargaining agent.

The employer should not be meeting directly with employees or with selected groups of employees if they are discussing anything that could impact wages, hours, and conditions of employment. They must first meet with the union committee. Be assertive about this. Demand that the meetings cease until they meet with the union. Do not agree that they will allow the union to sit in on the meetings as they happen. If the employer goes ahead and starts holding the meetings, then file a grievance (file it as a violation of the Recognition Clause/refusal to recognize the union) and attend the meetings so the union knows what is going on.

Now for some details on the steps listed above.

1. Stop, think, analyze

When the employer approaches the union about implementing a new program, the union committee must insist upon having time to sit down and think about what the employer has proposed. Employers will often try to rush the union into making a decision, thus hoping to get the union involved before it knows what is going on. One ploy of employers is to say they really don’t know what they want, they just want to try something different. Employers know exactly what they want, count on that. In contract negotiations the union usually takes a caucus after the employer makes a proposal, to discuss among the committee what the proposal really means. This is no different.

2. Assert the union’s rights as collective bargaining agent

Make sure the employer understands that no changes will be made to existing conditions without the union’s approval. Depending on past practice and specific contract language, the employer might be able to make some changes, but major changes in production methods usually run into contractual language. This gives the union power. If you’re unsure about the rights the union has, contact the UE Field Organizer assigned to your Local.

3. Ask questions, and demand answers

Get as much information as you can in writing. Often times they will have a manual that has been prepared for them by some consulting company. Demand a copy. These manuals are often very frank in stating what the employer should get out of the program. It might describe exactly how they will speed-up production, eliminate employees, or bust the union. Ask as many questions as you can and follow-up in writing. Make the employer reveal their intentions. Ask for names of other employers that have implemented this program.

The employer has answers, don’t let them kid you. If you think the program could cause changes in the production flow, ask to see the plans for redesigning the work flow. If the employer insists that they have no preconceived plans, that they don’t know what they want, tell them to come back to us when they do know what they want. Does the employer want better quality, faster production, cheaper production, better delivery of services? If they tell us what they want perhaps we can do something, BUT we will want guarantees in return. NO layoffs, no job cuts, no sub-contracting, no anti-union campaigns, higher pay, more training, job security, etc.

4. Analyze and figure out what the employer really wants

Once the union has gathered as much information as possible it is time to sit down and analyze what the employer wants. There are many factors to take into account.

If the employer has a history of anti-union behavior, then it is reasonable to be suspicious of any proposal they make. Do they really have a problem with quality that they want to fix, or is this just an excuse to start quality circles to divide the union members?

Make a list of what is good about the program (if anything) and what union members should be concerned about.

For example. The employer proposes a “pay for knowledge” program, where the more jobs a worker learns the more pay he/she receives. To many workers this sounds good. Extra pay is always welcome and finally the employer is willing to provide on-the-job-training.

The union lists the problems. What if a senior employee doesn’t want to learn extra jobs? Who gets laid off, a less senior employee with multiple skills or the senior employee with only one skill? Who gets the extra training? Does it go by seniority? Does everyone get extra training if they want it and get extra pay all the time? Does the employer really just want to offer this to his pets? With many multi-skilled workers who can be transferred to many jobs, will this cause permanent layoffs?

5. Discuss problem with the union members, stewards, national union representatives

The national union can provide many resources to help the local analyze the problem and come up with a plan of action. There are workshops available on cell manufacturing, Just in Time and other programs. It is important to get input from the union stewards and members as to what they think is going on. The committee must know if the supervisors are out working the floor, making promises to the membership. The strength of the union comes from its unity and organization. If members, officers and stewards are running in different directions, then we lose.

6. Educate the union members, stewards if necessary

Often times the employer’s plan may sound good to the membership. Vague promises of more money or job security get inflated when they are run through the rumor mill. The union may have to conduct an educational campaign as to the real nature of the employer’s proposal. Meetings, leaflets and lots of work by the stewards may be necessary to keep the membership united and on the right track.

7. Decide what the union wants, and make a plan.

If the union decides that the best approach is to just say “no,” then that is the plan. The union will have to be prepared for the employer not taking “no” for an answer. This can work if the membership is unified and understands what the employer is really up to. Part of any plan, the most important part, will be to figure out ways that the membership can express its opinion. Stickers, buttons, rallies are very important.

Often times we need a more complicated plan. The employer might have contractual language that will allow them to implement their plan. If that is the case then the union needs to figure out what to do to safeguard the members. The plan must include how the members will be involved in the company program.

In one UE shop the employer wanted department teams to make plans for improving production. The union’s demands were as follows:

- The union membership elected team members and could recall an elected team member.

- The union officers and department steward could attend every meeting.

- Union members could meet in caucus without management or a consultant present.

- The teams could not implement any changes in the department without a membership vote.

- No changes could lead to any layoffs.

- Any changes that affected the contract had to be negotiated by the union committee and voted upon by the membership.

What the employer really wanted was speed-up and layoffs and thus was stymied by the union’s conditions on participation. The “teams” soon disappeared.

Be bold in making plans. Make a list of every demand that will safeguard the members. Don’t be bashful about adding them to the list.

Make additional demands. If the employer wants the union’s help on setting up a cell then perhaps the employer should also be willing to talk about improving the pension. Employers don’t wait until contract negotiations to make demands, neither should the union. The union can demand that the employer invest in new equipment and machinery or hire more employees.

8. Negotiate with the employer and get an agreement in writing.

Oral promises aren’t worth much. If the employer’s intentions are “honorable,” then they shouldn’t be afraid to put commitments in writing. A no-layoff pledge isn’t worth anything if it was just a vague promise. The agreements should come before the program starts. Once the program has started and members are involved it will be hard to make the employer sit down and negotiate.

- The above article is used with permission and grateful appreciation from the United Electrical, Radio and Machine Workers of America (UE)

www.ueunion.org

Management Schemes Part 2 – A Short Glossary of Terms

Every month it seems like there’s a new management scheme introduced to the workforce. Like hula hoops, these fads come and go, but some have been around for awhile now. Even though many of these terms refer to manufacturing, a good number have been adopted for use in the service sector:

- Cell Manufacturing

- All the machines used to manufacture similar products are grouped together in a given area, instead of separate departments for each type of machine. Supposed to cut down on material moving and workers, by having workers cross-trained to run more than one type of machine or perform more than one function.

- Just in Time (JIT)

- A production system that does not use inventory. Products and parts are produced only when they are ordered and needed. Companies save money by having no inventory on hand. Since there is no inventory, workers can have a lot of control over the production process and therefore over the employer. Most JIT systems use heavy brainwashing so workers won’t use their power over the employer.

- Direct Flow Technology

- A variation of a Just in Time production system. Products are only produced when they are ordered, in the exact number that was ordered.

- High Performance Workplace

- A system where the union works with the management to cross-train everyone on skilled jobs and agrees that all non-skilled work can be farmed out to low wage shops.

- ISO 9000

- A standardized system of measuring quality, developed in Europe to ensure everyone was using the same standards. US companies that want to sell in Europe need ISO certification. ISO stands for “International Standards Organization.” In the US companies usually try to add team concept, or Just in Time and claim it is required under ISO regulations.

- Kaizan

- A Japanese system basically developed at Toyota Co. It means continuously improving production to make it more efficient. This usually means all idle time is filled with running machines.

- Kanban

- Originally a Japanese term for a sign that indicated a need for more parts to be produced. It is one of the many forms of Just in Time production.

- KITA

- A management by stress program developed by GE. It constantly moves workers around and lays off workers. It really means “A Kick in the Ass.”

- Lean Production

- When employers say they want “lean production” it means they want speed-up, job combinations and to do away with all “non-productive” workers, like inspectors, janitors, material movers etc. The remaining workers have to do it all. Lean production is often used to describe all the types of various management schemes.

- Management by Stress

- This theory reasons that improvements only come about when there is a certain amount of tension in the workplace. Bosses create this tension by constantly demanding more, in less time, with fewer employees. They also create tension by demanding changes in how work is done, even if no change is really needed. A by-product of “management by stress” is also known as “workplace violence.”

- Pay for Knowledge

- A system where workers get paid more as they become cross-trained and learn other jobs. This tends to compress job classifications into a few large categories so workers can be transferred to any job in the classification. It often fails because the employer wants to pick and choose who gets trained.

- Push-Pull Systems

- A “pull” system means that manufacturing is only done when orders come in. The orders “pull” the product through the factory. Direct Flow systems are “pull” systems. A “push” system refers to a company pushing parts and products through the production process whether or not they have orders.

- Quality Circles

- Workers form circles to discuss with the boss ways to improve quality. Bosses use this to get workers to complain about each other and to by-pass the union structure.

- Self-Directed Workforce

- A program where employers get rid of foremen and make the workers manage themselves. This can be fun if all the workers agree not to rat each other out.

- Six Sigma

- A program of statistical process control developed by Motorola and expanded upon by GE which is pitched as a way to cut defects and eliminate rework. Through process mapping and other techniques, the objective is for the company to gain complete knowledge and “control” of the work process. This leads to increased standardization of jobs, less reliance on the skill and knowledge of the workers, and helps pave the way for the transfer, speed-up and elimination of work.

- Statistical Process Control (SPC)

- A system where workers carefully document how their machine runs and all the steps they take to produce a product. This is supposed to help maintain quality, but usually it is used to eliminate in process quality inspectors.

- Team Concept

- A variation of quality circles. Workers form teams in each work area and compete with other teams to produce the most for the boss. This usually comes with heavy brainwashing sessions on why workers and the employer should be buddies.

- Win-Win Bargaining

- A supposedly non-confrontational form of negotiations. Neither side is supposed to prepare an agenda or demands. The problem is, the boss always has an agenda.

- WorkOut

- A GE program ostensibly designed to encourage “boundaryless” behavior by encouraging open group discussion of work-related issues between workers and management. In reality, it is a means by which the company accesses the workers’ ideas and knowledge of their jobs to cut costs and to ratchet up productivity. Also known by GE workers as the “out of work” program.

- Worker Empowerment

- A term bosses use when they want workers to help them improve quality and speed-up production. Having the power to speed-up work is supposed to make workers feel “empowered.” Worker empowerment does not apply to deciding on who gets the profits, setting work schedules, deciding what country to produce in, or any other item that really matters.

- The above article is used with permission and grateful appreciation from the United Electrical, Radio and Machine Workers of America (UE)

www.ueunion.org

Plant Closings (WARN and Warning Signs)

The (few) protections for workers facing plant closings

Issues

- There are not many protections for U.S. workers facing a plant closing. Stewards and union officers must be familiar with the few that are available – especially the WARN act and similar state laws.

- The WARN act requires 60 days advance notice of a closing in certain situations – unfortunately, many workplaces are too small to be covered by WARN (remember, bosses fought hard against even this limited legislation).

- Many times, a closing can be predicted, prepared-for, and even averted by keeping a watchful eye on what’s happening at work.

Note: This article was published in 1997

The WARN Act

Offers Some Protection

It does not offer a lot of protection — but at least it offers some warning to some workers in possible plant closing situations

The Worker Adjustment and Retraining Notification Act of 1988 (WARN Act) is intended to give workers, their families and the community sixty (60) days advance notice by an employer of any plant closing or mass layoff (unions can negotiate longer notice times). The employer must provide this notice to the union, to the elected officials of the town or city where the workplace is located and to the proper state officials.

WHO’S COVERED?

The WARN Act covers any employer with more than 100 employees, including all office and supervisory personnel. Workers who have not worked for the employer more than 6 months out of the last 12 and workers who average less than 20 hours per week are not counted.

WHAT TRIGGERS THE WARN ACT?

Plant closing: Notice must be given if a workplace or part of a workplace will be shutdown and 50 or more employees during a 30 day period will lose their jobs.

Mass layoff: The same 60 day advance notice must be given if there is to be a mass layoff not due to a plant closing but which will result in an employment loss during any 30 day period for 33% of the total active workplace (or 500 workers, whichever is fewer).

Sale of business: If any of the above thresholds are met during a complete or partial sale of a business then WARN Act notice must be given. If the closing or layoffs occur before the sale then the current owner is held responsible for giving the notice. If the new owner closes or initiates a mass layoff, the new owner is held responsible for giving the notice.

Definition of employment loss: Any termination of employment, (except for discharge for cause, voluntary quit or retirement) caused by a layoff exceeding 6 months or a reduction in an employee’s hours of work of more than 50% in each month of a 6 month period. The employer can get around this definition of “employment loss” by offering an employee a job transfer to another worksite that is “within reasonable distance.”

WARN ACT ENFORCEMENT

Unfortunately the WARN Act must be enforced by suing an employer in US District Court. The lawsuit can either be filed by the workers, the union, the city or town or an individual.

Penalties for failure to notify: An employer who violates the WARN Act can be held liable by the courts to pay employees up to 60 days back pay and benefits. This is reduced by the amount of pay workers actually received during the 60 day period prior to the closing or mass layoff.

There are exceptions to the notification rule. For example if it is beyond the employers ability to give proper notice, as in the case of a natural disaster or a sudden, unexpected cancellation of a large order by a customer. Many employers try to get around giving notice by laying off workers bit by bit so that a layoff doesn’t appear to meet the “mass layoff” qualifications. Other employers have tried to layoff workers so that the total number falls below 100 employees when they finally close down the workplace.

STATE WARN ACTS MAY BE BETTER

Many states have laws which mirror the federal WARN Act. Some provide greater protection and services. If faced with a shutdown or mass layoff, make sure you contact the state agency which handles labor relations matters.

Although the WARN Act does not stop an employer from shutting down it does give us time to organize to stop the workplace from closing. This is the most important aspect of the law.

Early Notice of Warning

Signs May Save Your Plant

Many diseases once thought fatal can now be minimized by recognizing the warning signs and seeking early treatment.

The same is true for the damage caused by plant closings, but too few of us recognize the warning signs. And often we don’t realize that “medicine” exists to fight shutdowns.

Long before your employer issues a WARN Act notice (see the accompanying article above), there will be tell-tale signs that your workplace could be in trouble.

WARNING SIGNS

WARNING SIGNS

Although the circumstances of every plant closing are different, there are some things we should keep our eyes open for:

- Disinvestment – Lack of equipment or building maintenance. Removal of equipment. Profits used to improve or buy other businesses.

- Ownership problems – Change of ownership. No successor for an aging owner.

- Declining Sales/Employment – Loss of major customers. Business doing worse than the rest of the industry, especially for three years or more.

- Duplicate Capacity – Twin location with ability to make the same product. Movement of least-skilled work.

- Management Instability – High turnover at manager, engineer or labor relations positions. Mysterious “consultants” appear.

- Changes in Land Use – Neighboring plants being sold and converted to non-manufacturing uses.

- Inadequate Research & Development – No new products. Losing ground to other companies in product design and quality.

- Money Trouble – Supplies arriving COD. Lack of supplies screwing up production. Paychecks bouncing. Taxes delinquent.

And sometimes, the first warning sign is a rumor of a closure.

Right now, you’re probably thinking, “Hey, that’s my workplace!” Don’t panic. Any of these warning signs may not necessarily signal that the end is near, but should serve as a wake up call to keep your eyes open.

STEPS TO TAKE

But let’s say the writing is on the wall. Is there anything a union can do to turn a doomed operation around?

First the union leadership must make an honest assessment of the situation. Sometimes what management needs is genuine constructive criticism to get back on track. The union can be helpful in identifying where management has gone wrong, even coming up with potential new products and markets.

More often, the local must organize itself for a full-blown fight back. This usually includes organizing the membership, the community, churches and other unions to pressure the employer to keep the workplace open. Elected officials from city council members all the way up to governors and congressmen have been enlisted by UE locals to help keep jobs in a particular community, city, or state.

NEW OWNERSHIP?

When a company is determined to leave a particular location or market, UE locals have successfully attracted new, potential owners for a plant and pressured the old owners to sell and, on rare occasions, has used eminent domain (when a governmental body takes over a workplace to seek new owners or turn it over to the workers themselves) to save jobs.

All of these strategies are explored in the pamphlet Refuse to Lose: Eminent Domain and the JC Rhodes Campaign, published by the UE Education Department and available from the national office.

MORE INFORMATION:

More Info on WARN may be found at: Department of Labor Compliance Info

- The above article is used with permission and grateful appreciation from the United Electrical, Radio and Machine Workers of America (UE)

www.ueunion.org